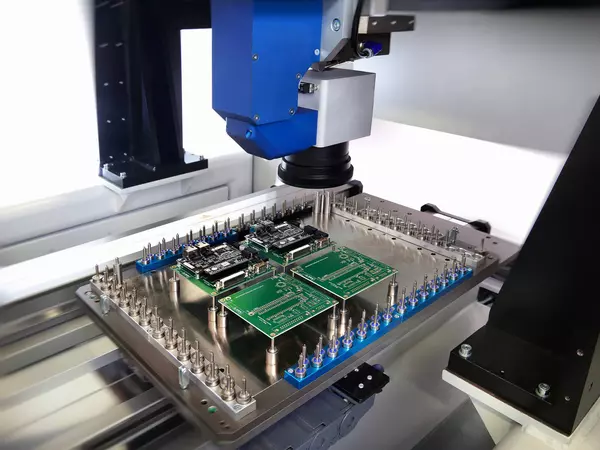

The compact stand alone machine with speedLAS? technology allows precise high-speed laser machining thanks to the innovative interplay between SCHUNK linear axis technology and laser scanner control. The laser shortens process times and ensures at the same time an optimal cutting quality. Lasering with the appropriate source in each case as well as the possibility of combining laser machining with milling technology on one machine create a high degree of flexibility.

In the speedLAS? technology, the laser is controlled by a special scanner in such a way that its movements overlap with those of the axes. This innovative method ensures that the laser is always aligned at the optimum angle to the workpiece, resulting in precise and straight cuts. The use of this technology delivers an aesthetically pleasing cutting quality, but also leads to an up to 80% faster processing speed compared to previous laser applications. In addition, the energy input in the edge area is optimized, which further increases the efficiency and quality of the cutting process.