As a specialist in automation and production, we support our customers in making their processes efficient, transparent and sustainable. Our holistic three-step approach will increase our customers' productivity and competitiveness – from on-site consulting and feasibility analyses to the use of our standardized GROW automation cells.

Contact us for a non-binding consultancy appointment at automationsolution@de.www.baby7.net

At SCHUNK, we understand that having the right automation makes all the difference. That's why our three-step approach to increasing productivity starts with a personal visit to your premises from our experts. Our goal is to work together with you to tap into the potential of your production systems and to identify manual processes that can be optimized with our standardized GROW automation cells.?

Contact us today to arrange an appointment for a no-obligation automation check on site. We look forward to taking the first step towards an increase in productivity with you.

We carry out realistic feasibility analyses in our robot application centers, making it easier for you to take the step towards automation. We validate the automation potential identified for your company, show you solutions for process automation and minimize the technical risk.

SCHUNK standardizes entire processes such as laser marking and parts separation – in a modular system.

Our CE certified, turnkey GROW automation cells impress with quick commissioning and intuitive operation – with no need for any prior knowledge of robotics.?

Their modular design means they can be flexibly adapted to your individual requirements. The use of proven components guarantees reliable performance and specifically increases the productivity of your manufacturing.?

The GROW marking is based on high-quality premium components and impresses with simple operation. With a high-performance laser, important information such as serial numbers, manufacturer details, product designations, quality marks or DMC codes can be precisely and permanently lazered onto products.

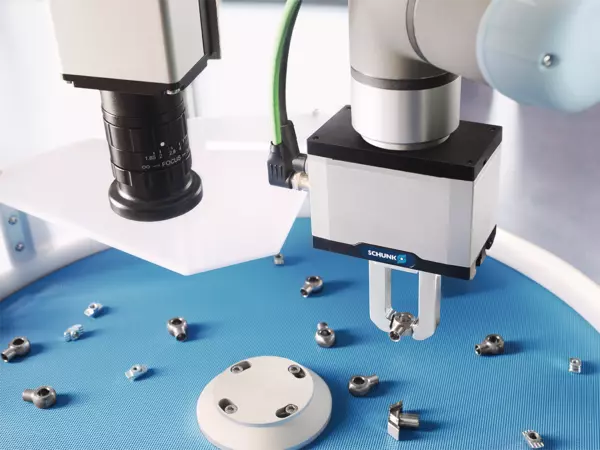

The foundation for GROW sorting is the AI-based vision system 2D Grasping-Kit from SCHUNK. It enables flexible separation of bulk goods in combination with a wide range of automation components.

For example, through the integration of additional process modules, simple mounting tasks can also be taken on within the automation cell.