A shortage of skilled workers, demographic change, sustainability targets, and growing competitive pressure: more and more small and medium-sized enterprises are under pressure to make their production processes more efficient. Automation not only provides an answer to the lack of manpower, but also enables productivity increases and greater process reliability. Automating simple manual tasks such as palletizing, assembly, or sorting can free up valuable personnel resources and increase quality at the same time.

But as great as the interest is, there is often a lack of orientation: many companies do not know exactly where to start. You have initial ideas – such as automating a manual handling step – but are unsure whether this is even suitable. Others recognize the pressure to act, but have no specific idea about which process could be automated. This is precisely where a structured three-step approach comes in, making it easier for companies to get started.

The first step begins with a completely open and transparent appraisal of the general situation: What manual activities are carried out in the company? Where are recurring, monotonous, or physically stressful processes? And which of these can potentially be made more efficient through automation?

In practice, companies are often initially guided by obvious problems – such as the fact that an employee will be retiring in the near future or that an activity is perceived as relatively unergonomic. Here, it is helpful to broaden the scope and consider the entire process with its upstream and downstream process steps, instead of just the individual work step. For example, it can make sense not only to automate the removal of a component from a machine, but also to directly integrate a visual inspection by camera or even to include the next production step – such as deburring.

The needs analysis is therefore not only about the "if", but also about the "how". Which components should be processed automatically? What are the quality requirements? How many parts should be produced per day – and how much can the solution cost in order to be cost-effective? Companies that take a structured approach here often identify greater potential than initially thought. And they avoid bad investments because they do not rush into unsuitable or overly complex processes.

Your colleagues at the machine know what they are doing: analysts often overlook a work step, such as a quality check by means of a simple visual inspection, the provision of boxes, or the like. The change of perspective provides valuable knowledge for the needs analysis!

Once a suitable process has been identified, the next question is whether it can be automated at all. What is called the validation phase serves to find out exactly that – ideally before large investments are made.

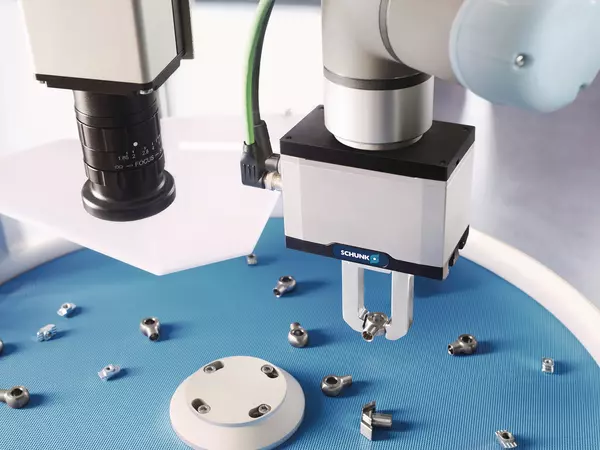

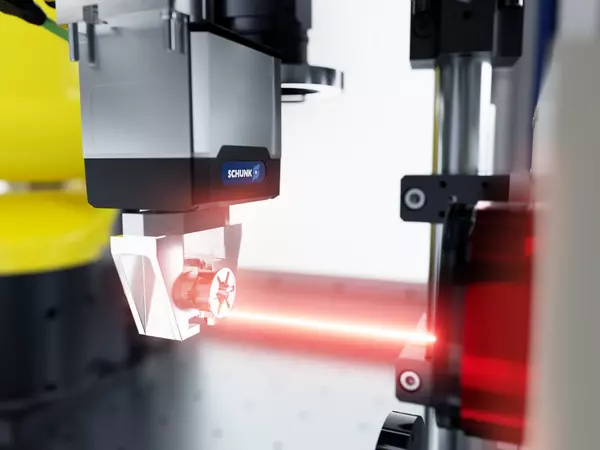

The focus is on the core process, by which is meant the step that generates the actual added value – such as laser marking, screwing, or sorting. It is advisable to check this first before dealing with peripherals such as feeders or storage racks. In practice, this means: Does the gripping of the component work? Does the vision system recognize the correct position? Can the desired result be reliably reproduced? Only when it is clear that the central automation step works reliably are the other process details considered, such as separate rotary units, the cell, or a conveyor belt. Many companies find validation stressful and risky, as they would have to buy the robot or manipulators beforehand in order to test the automation in practice. What if it then turns out that it doesn't work as expected? It is normal for solutions to have to be fine-tuned during the validation phase or, in some cases, for new solutions to be developed. A complete loss of investment is rare after a good needs analysis.

Don't get bogged down with side issues: instead, concentrate first on the core process that creates added value for you. The rest will come later.

Once the technical feasibility has been confirmed, the next step is implementation: installation and commissioning in production. This step is complex and the most difficult hurdle for many small and medium-sized enterprises. This is because successful implementation includes mechanical and electrical design, selection and procurement of all components, installation of the system, programming and commissioning, including safety technology. Details such as communication between system components, programming of different workpiece variants, integration of safety functions, supply of energy or compressed air must be taken into account – and all of this must work together in a functioning overall system. This step usually requires several specialized experts, which is why it is usually not affordable for many companies without external support.

Many details arise in the implementation question, such as safety considerations or robot programming. Solving them takes time – so it's better to include a little slack in the schedule.

How can companies be sure that a process is actually suitable for automation in the first place?

By including external expertise in their needs analysis. At SCHUNK, we offer a non-binding and free initial consultation with the automation check. On site, our experts analyze the processes together with the customer, identify automation potential, and prioritize the relevant applications – including a view of upstream and downstream process steps.

How does a company establish that a planned automation system will also work technically – without having to make large upfront investments?

There are ways to test the hardware without having to buy it first. For example, in one of the 15 SCHUNK CoLabs worldwide, two of them in Germany and one in Austria. If desired, the technical feasibility of the core process is checked together with the customer. SCHUNK uses real components to test whether, for example, grippers, vision systems, or processes such as laser marking work reliably. This minimizes the technical risk – without any upfront investment by the customer. Validation in the CoLab is free of charge for end customers with a specific project interest.

How do companies make the implementation phase easier?

Instead of designing a special machine from scratch, companies can fall back on standardized solutions that have already been produced. These are configurable, quickly ready for use, and economical. In many cases, this is all that is needed for relatively simple processes such as sorting, laser marking, or assembly. SCHUNK supports the implementation of standard components and assemblies through to comprehensive complete solutions. The complete solutions designed as modular systems and building blocks are ideal for automating simple processes such as laser marking or separation. They therefore cover the automation tasks typically required by small and medium-sized enterprises. This simplifies work processes and makes them more efficient in order to quickly offer tangible added value and increase productivity.