Wherever inaccuracies or tolerances in robot-assisted manufacturing processes, SCHUNK’s AGM compensation unit truly comes into its own. Thanks to its modular design and patented technologies, the AGM handles a wide payload range – from just a few grams to 400 kilograms. The extensive portfolio includes over 50 variants for compensation in all directions (XY, Z, W, XYZ und WZ) and is perfectly tailored to meet the demands of modern manufacturing. With this wide variety of options, users are sure to find the right unit for every application.

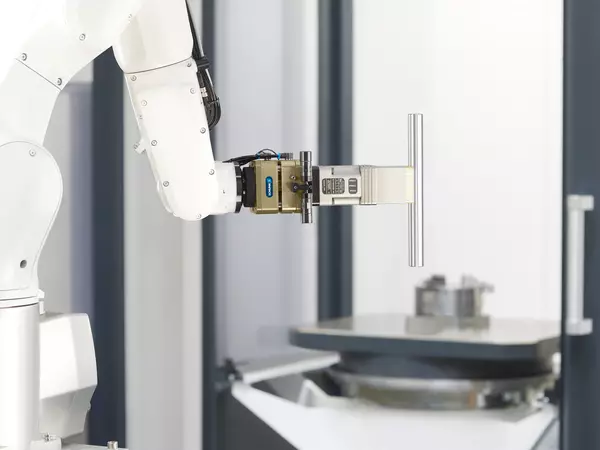

During loading and unloading of machine tools, tolerances can cause interference between the workpiece and gripper, disrupting processes and leading to errors. The AGM-XYZ variant compensates for these inaccuracies, thereby enhancing process stability.

Its compensation behavior in the X-, Y-, and Z- directions enables precise positioning of components. This reduces interruptions and ensures smooth operation. Optionally available patented, manually adjustable spring cartridges keep the compensation unit centered. Depending on the size, different force ranges are possible, allowing optimal adjustment of weight compensation. Additionally, optional sensors can detect the locking and unlocking of the AGM without adding extra interfering contours, thereby simplifying process monitoring.

In automated joining processes, positioning or component tolerances pose significant challenges that can lead to scrap, rework, or downtime. Since a wide range of components is handled – from delicate electronic boards to large engine blocks – a flexible and precise solution is required.

The AGM-XY variant reliably compensates inaccuracies and offsets in the X- and Y- axes, thereby simplifying the joining process. Thanks to the manually adjustable stroke, the compensation path can be flexibly adjusted. The smoothly running guidance concept is ideally suited for the handling of delicate or fragile components. Additionally, the stroke limitation allows for adjustment of shorter strokes, enabling the execution of challenging joining processes. Its compact design also ensures suitability for space-constrained applications.

In bin picking, the major challenge is the undefined position of the components: their geometry must be detected and securely gripped while removed without collision. During removal, the position of the parts can constantly change, causing misgrips and delays.

Here, the AGM-W is angularly compensating, and the gripper can safely pick up components arranged in different positions without mutual jamming. The compensation force of the angle can be precisely adjusted via compressed air, allowing accurate compensation even in tilted orientation. Here, optional sensors also facilitate process monitoring.

In addition, the pneumatic locking and unlocking enables highly dynamic processes with fast travel paths. This allows efficient, damage-free separation and complete emptying of the bin, even with fragile components. The AGM-W thus increases productivity and reduces downtime in automated storage and logistics processes.

SCHUNK offers a broad portfolio of compensation units that can be individually adjusted to various industry requirements and applications. The versatile solutions impress with flexible applications and ensure efficiency, reliability, and precision in automation. For specific requirements, an experienced SCHUNK engineering team is available to work with customers to develop tailored solutions.