What does the future of manufacturing look like? Our answer: flexible, precise, automated. Visit us at EMO Hannover 2025 and discover how our innovative clamping devices and global engineering expertise can make your processes more efficient and future-proof.

We offer the perfect solution, whether safe clamping solutions for complex workpieces, efficient machine loading or future-oriented automation. Our experts will be on hand to present this year's highlights: intelligent, electrically powered clamping systems and battery-powered solutions. Set new standards in metalworking - with us!

In addition to our innovative automation solutions, we offer a comprehensive portfolio for workpiece clamping in the machine with low set-up times. Our new clamping solutions are ideal for machining complex workpieces or small batch sizes and help you to optimize your processes. Interested? Learn more at the booth!

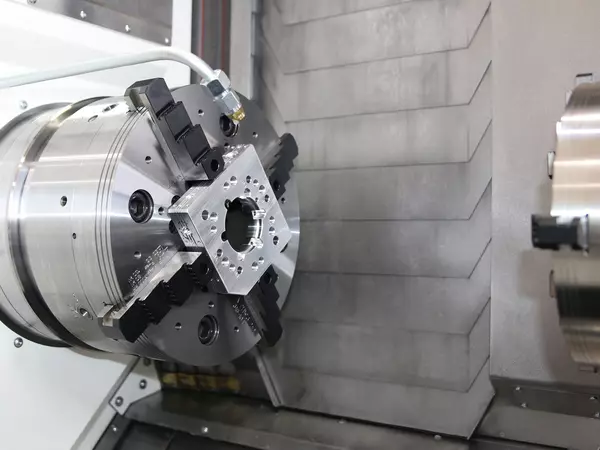

SCHUNK also relies on flexibility for lathe chucks. The new ROTA THW3 2+2 power chuck enables centrically compensating workpiece clamping for various geometries. Thanks to its patented sealing, permanent lubrication and quick jaw change system, it combines low maintenance, short set-up times and high clamping forces.

The KONTEC KSC-5X expands SCHUNK's 5-axis clamps with a centric clamp for demanding machining operations. Higher base jaws and a unique selection of system and top jaws enable complex workpieces to be clamped when machining in 5-axis machining centers. With its quick-change spindle system and integrated zero-point interface, it offers fast adaptation and seamless integration into SCHUNK's modular clamping technology system.

SCHUNK offers the best solution for every tool clamping challenge. Our portfolio ranges from mechanical tool holders, heat shrink holders and low-vibration precision holders to the innovative TRIBOS polygonal clamping technology and TENDO hydraulic expansion technology. Discover our new products now!

SCHUNK is expanding its TRIBOS Mini portfolio and setting new standards in micro machining. The new TRIBOS Mini HSK EZ15 impresses with an optimum mount to cone ratio, allowing the full performance of modern micromachines to be utilized. Thanks to its rotationally symmetrical design, it guarantees the best surface quality, even at high speeds. The minimal interfering contour enables maximum flexibility in 5-axis machining.

SCHUNK intermediate sleeves enable the clamping of various shank diameters with just one toolholder. The new Performance intermediate sleeve can be used in the SCHUNK TENDO, TRIBOS and SINO-R toolholding system and in all commercially available hydraulic expansion toolholders and power chucks. Thanks to the pull-out protection, CoolFlow technology and active clamping mechanism, it extends tool life, reduces cutter breakage and improves dimensional accuracy. Ideal for dynamic milling strategies and demanding workpieces, especially in aviation and mechanical engineering.

Sometimes you need more than one standard component. For this purpose we have the SCHUNK Engineering : From a simple adaptation to complex individual clamping or automation solutions that have to be developed from scratch, everything is possible. We understand your processes and provide you with support exactly where you need it. In addition to its extensive and high-quality component portfolio, SCHUNK offers a proven engineering process that has been optimized over decades for the development of customized solutions.

This process is based on in-depth expertise, technical excellence, rapid implementation and global availability in the areas of project management, design, production, assembly and after-sales service.

Be it E-Mobility or Life Science – SCHUNK stands for cross-industry engineering at the highest level. With decades of expertise, precision and a pioneering spirit, we master your individual challenges and develop solutions that go far beyond any standard approach. Exactly how you need it.

With the increase in automation and the digitalization of machine tools, the focus is increasingly shifting to the electrification and monitoring of processes. Electrical and sensor-based clamping systems from SCHUNK make it possible to monitor the process-relevant status of the clamping devices and workpieces or the vibration behavior of the tools in real time. As a result, they not only offer greater safety and end-to-end transparency, but also simple integration into existing machine control systems - an important basis for the production of the future. One absolute highlight at the EMO are our battery-powered clamping devices, which can be wirelessly integrated, by radio, via solutions from common measuring system providers or via IO-Link wireless. See for yourself at a live demonstration of the advantages of these technologies.

"As a technology pioneer, we are resolutely driving the transformation of manufacturing towards digitalized, sustainable and highly efficient processes. Electrical and sensor-based clamping systems are important components with a view to fully exploiting the potential of automation and networking. At EMO 2025, we will present how SCHUNK is shaping the production of the future with a pioneering spirit and strategic foresight - always with a clear focus on the success of our customers." - Markus Kleiner, Managing Director of H.-D. SCHUNK GmbH & Co. Spanntechnik KG